The trend towards using 2-wire irrigation systems comes from the USA and is becoming increasingly important in the professional sector. Here I explain what distinguishes a two-wire system from a conventional system and what advantages and disadvantages it has.

In principle, 2-wire systems have existed for many years and have so far been used primarily in the golf industry. In the USA, these are now becoming increasingly widespread in the private and commercial sectors, which is also due to the fact that more and more irrigation professionals are now familiar with this technology.

The difference between a 2-wire system and a traditional irrigation system is that all solenoid valves and sensors are connected to the irrigation computer using the same 2-wire cable harness. The 2 wires lead from the irrigation computer first to the first solenoid valve, from there to the second, then to the third, etc. etc.

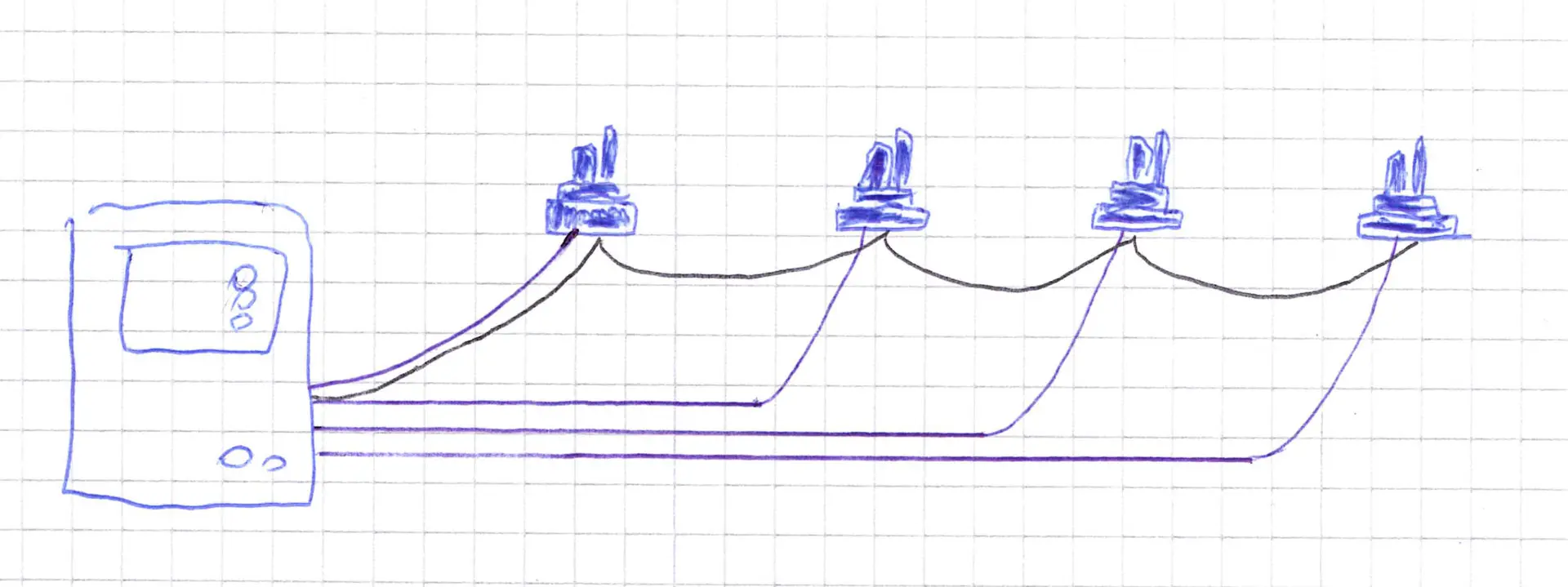

In contrast to a traditional system, in which a wire that controls the valve is led from the irrigation computer to each solenoid valve. And in addition, a common wire is used as a neutral conductor. For example, if an irrigation system uses 8 solenoid valves, then a total of 9 wires are required; if it consists of 20 solenoid valves, then 21 wires are required. If a solenoid valve is to be switched, the irrigation computer sends voltage via the cable connected to the valve.

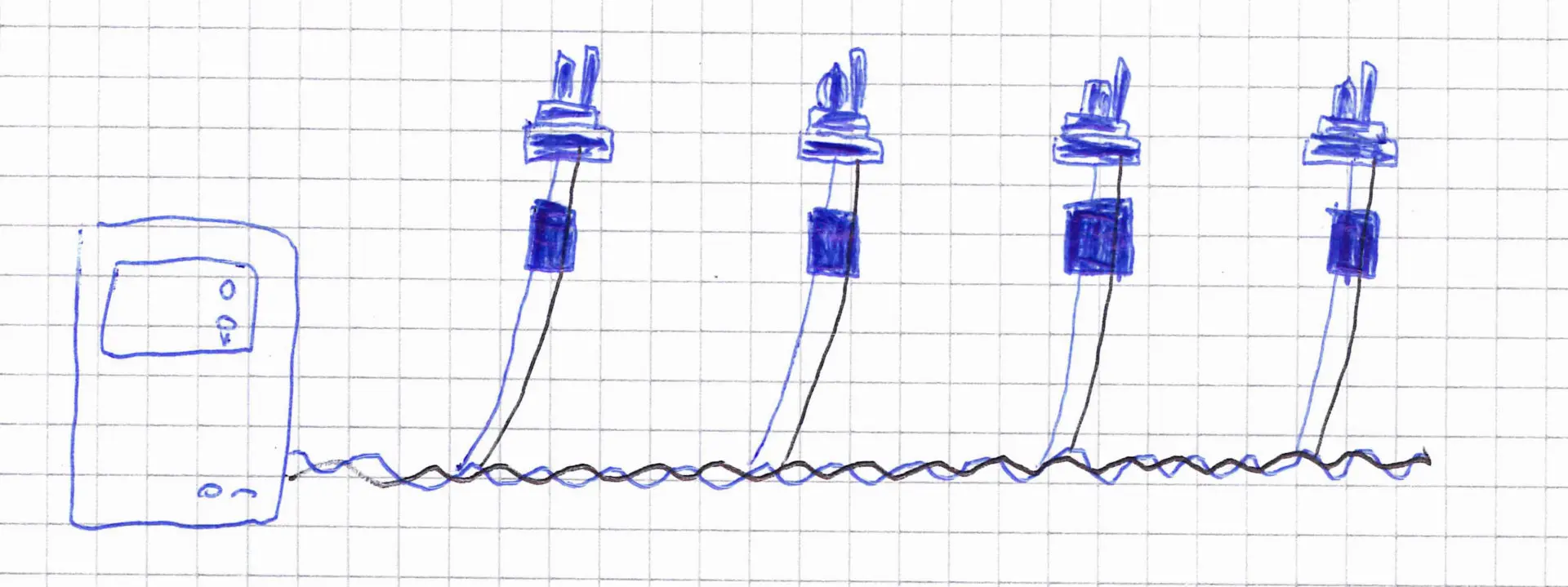

Below I have shown this graphically in a simplified manner. On the left is the irrigation computer, next to it are the solenoid valves attached to it and the cable connection in between:

Conventional system, an additional wire is added for each additional solenoid valve, the neutral wire is shared

2-wire system, all solenoid valves are connected to a two-pole cable via decoders

With a 2-wire system, you only need 2 wires, regardless of the number of valves and sensors connected. The system is intelligent and automatically communicates with the right recipient. This works with additional decoders that are placed in front of each solenoid valve and each sensor and have an individual address. If you want to switch a solenoid valve, the irrigation computer speaks to the decoder that is connected upstream of the desired valve and this opens the valve.

Unlike the conventional system, the 2-wire system is not one-way, but enables two-way communication. The decoder can not only receive commands, but it can also send information back to the irrigation computer. Status information from valves and sensors can be reported back and modern irrigation computers can send automatic warning messages based on this if there is a problem.

In addition, expanding an existing system is much easier than with a conventional system. With the conventional system, a new cable would have to be pulled from the irrigation computer to the newly added solenoid valve; with the 2-wire system, this can simply be continued from the point closest to the existing irrigation system. This can potentially save a lot of effort on excavation work. Alternatively, if desired, a second and third 2-wire cable harness can be created in a 2-wire system if this is more advantageous than continuing the existing one.

In summary, using a 2-wire system has the following advantages.

Advantages of a two-pipe irrigation system:

- Fewer cables are required and costs for the increasingly expensive copper cables are saved

- For very large irrigation solutions, a computer can control a much larger number of valves (200 or more). Conventional computers usually have a maximum of 54 valves. This saves costs for additional irrigation computers and allows everything to be controlled centrally on one computer.

- 2-wire systems have a significantly greater range than conventional systems, meaning valves/sensors that are very far away can also be connected.

- Two-way communication allows problems to be reported back so that they can be identified and resolved early

- Subsequent expansions of the system are very easy

On the other hand, 2-wire systems also have disadvantages compared to conventional irrigation systems.

Disadvantages of a two-pipe irrigation system:

- A specially designed irrigation computer and components are required (note the exception below). These do not operate with the usual 24 volt alternating current voltage but with 30 volt direct current. Use with existing components is therefore not possible.

- Every solenoid valve and sensor must be preceded by a decoder, which effectively acts as their brain. There are additional costs for this.

- If the two-wire cable harness is damaged in one place, all valves and sensors located after this point will fail in one fell swoop. In such a case, a very quick reaction is necessary and it should be precisely documented how the cable harness runs underground.

- 2-wire systems have high installation requirements. High quality cable with double covered insulated twisted wire and solid core must be used. The jacket should be made of polyethylene and not PVC. The connection points must also be waterproof and the decoders must be grounded with ground rods to protect them from static electricity.

So you can see that in return for the possible savings, a lot of additional effort is required. In addition, the installation is more complex, so it should always be carried out by a specialist and here too you have significantly less choice as not all professionals are trained in this system. In expert circles, a 2-wire system is viewed as a cheaper alternative to a conventional irrigation system for systems with at least 25 to 35 sectors.

2-wire systems are offered by major manufacturers such as Rain Bird and Hunter. Hunter offers the ACC2 decoder controller (75 to 225 sectors) and the ACC-99D decoder controller (up to 99 sectors), Rain Bird has the 2-wire decoder controller ESP-LXIVM (60 to 240 sectors) and the 2-wire decoder controller ESP- LXD (50 to 200 sectors) in the range.

Due to the high requirements for installation and materials to be used, combined with the resulting usefulness only for very large projects, 2-wire systems currently hardly play a role for the typical private user. But that could change in the next few years, because in manufacturer circles the 2-wire system is seen as the system of the future. At the end of 2019, Hunter took an important step towards making the 2-wire system more attractive for private use with the introduction of its EZ Decoder System (EZDS). The EZ system (pronounced “easy”) can be retrofitted into an existing solution and avoids many of the previously existing disadvantages of a 2-wire system.

EZ decoder system from Hunter

No special 2-wire irrigation computer is required for this, but existing irrigation computers from the Pro-C, HCC and ICC2 series can be converted to a 2-wire system with an additional expansion module or a hybrid solution is also possible, i.e. some of the valves can be controlled using conventional ones system and the other part using a two-wire system.

To convert, the expansion module is connected to the existing computer and the 2-wire cable harness is then routed from the expansion module to the solenoid valves and sensors. Unlike previous solutions, the existing valves and sensors can continue to be used because the EZ decoder system works with the same 24 V voltage as the conventional systems. Existing cables can also be used. Only one EZ1 decoder needs to be placed in front of the valves and sensors so that they receive the unique address required for the 2-wire solution.

The very high installation requirements of previous 2-wire systems are no longer required: normal cable can be used and the decoders do not need to be grounded.

Pro-C computers can be converted into a 2-wire system with a PC-DM module. Up to 28 decoders can be attached to this. HCC and ICC2 computers are retrofitted with an EZ-DM module, which allows up to 54 decoders.

The EZDS system offers a comparatively cheap and, above all, quite easy way to switch to a 2-wire system or to convert only parts of the system to it in the first step. The functionality of the irrigation computer is completely retained during a conversion. There is currently no Rain Bird equivalent to the EZDS system, but it can be assumed that this will happen soon.

My point of view: The introduction of the EZDS system is an important step and could give a strong boost to the spread of 2-wire systems in the private sector. In my opinion, a certain stumbling block could still be the quite high price for the EZ1 decoders, which are currently available in stores for around 50 to 60 USD each. Since one decoder is required for each solenoid valve, this adds up quite a bit. One can hope for future price reductions here.