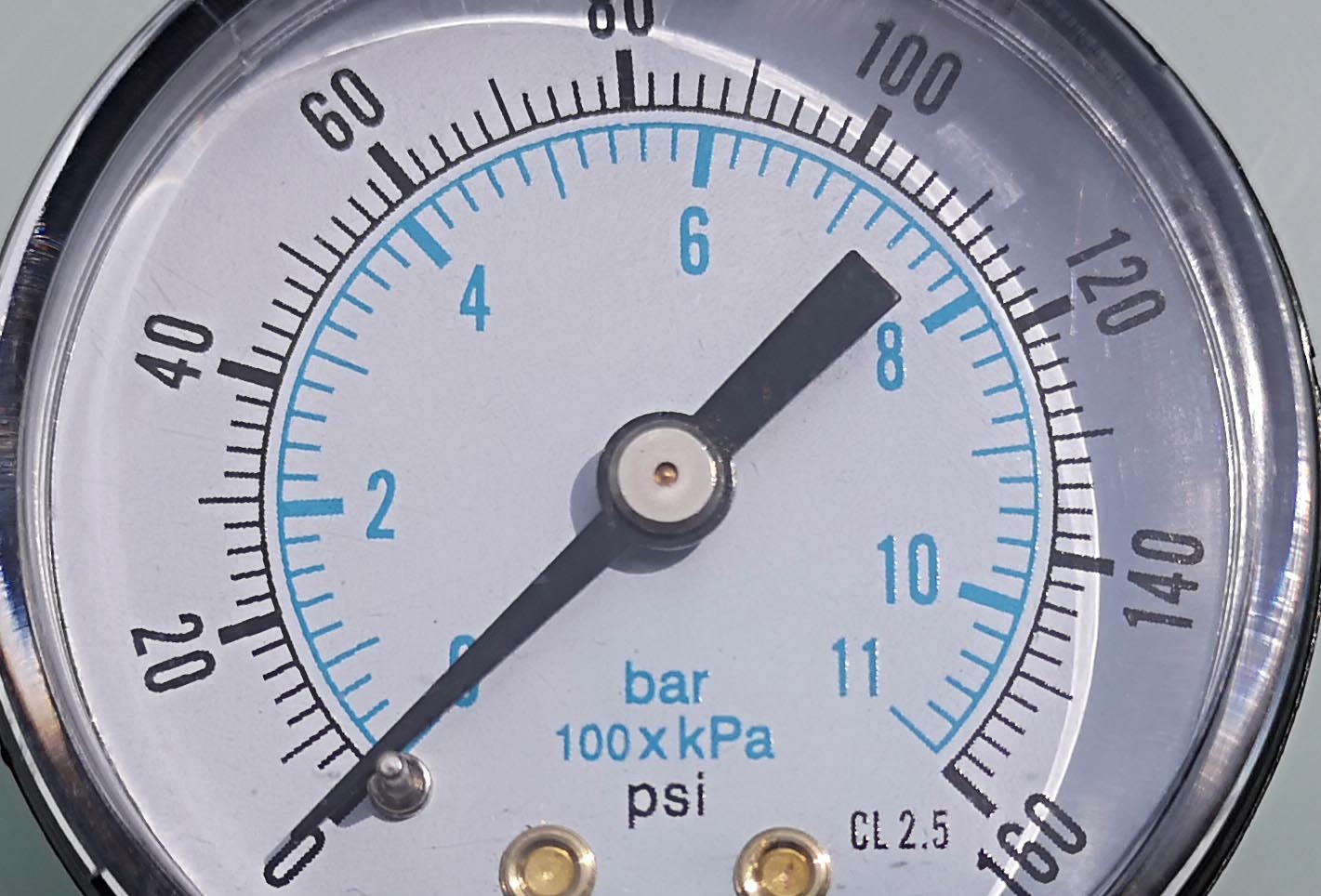

Knowing the existing water pressure at the point where the irrigation system draws water (see Planning, Chapter 1) is a good start, but only half the battle. Because this pressure does not reach the sprinklers in full. On the way to the sprinklers, the water in the pipeline has to overcome resistance that slows it down and thus reduces the water pressure. You will then find approximate values that can be used for this purpose and, alternatively, an option to calculate the loss in detail yourself.

To understand what happens to water pressure in an irrigation pipeline, imagine the following 4 levels:

- Water is let out of the fully open outdoor faucet without trapping it

- Water is drained from the fully opened outdoor faucet into a wide stovepipe (4 inches)

- Water is drained from the fully opened outdoor faucet into a 3/4 inch irrigation pipe

- Water is let out of the fully opened outside tap through a funnel into a straw

In the first scenario, the water does not encounter any resistance. This corresponds to the water pressure that is measured at the water extraction point. It is the same in the second scenario, in which the water flows into a very wide pipe. The water has more than enough space to flow unhindered, the water pressure loss is also practically zero here. In the third scenario, the diameter of the 3/4 inch pipe is no longer sufficient to allow unhindered flow. The friction results in a (slight) deceleration of the water flow and the water pressure decreases. This applies even more to the fourth extreme scenario, in which the water is passed through a straw and a large part of the existing water pressure is lost in the process. At the end of the straw there is only a small trickle with minimal water pressure.

How strong the water pressure loss is depends on the pipe diameter and two parameters in particular:

- The length of the pipe

- The amount of water that flows through the pipe

The following applies:

- The longer the pipe, the greater the loss

- The greater the amount of water, the more noticeable a restricting pipe circumference, i.e. the greater the pressure loss

Approximate calculation

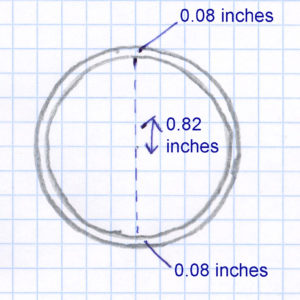

You will then find approximate values with which you can work as part of your irrigation planning. These are calculated for the common 3/4 inch pipeline, which is mostly used in the private sector. This typically has a wall thickness of about 0.08 inches and an inside diameter of about 0.82 inches through which the water flows.

Sketch of a 3/4 inch irrigation pipe

The water pressure loss is given for a certain amount of water per hour. That is the amount of water that runs through the pipeline per hour. This amount of water is smaller than the amount of water that is available to you at your water connection (see bucket test for calculating this value). If you use the values of the bucket test, you are completely on the safe side and still have a small buffer.

For the various water volumes from 320 to 950 gallons per hour, the pressure drop is indicated for a pipe length of 30, 60, 90, 120 or 150 feet. Since this loss increases constantly with increasing pipe length, you can easily determine values for longer pipe lengths yourself by updating the table values. The pipe length is the length of the underground pipeline between the water extraction point and the most distant sprinkler. And always for each sector. If you divide the pipeline into several sectors, then the pressure loss has to be calculated separately for each sector and thus the pipe length of the corresponding sector is relevant.

The pressure loss in a 3/4 inch pipe is therefore roughly:

| Amount of water | 30 feet pipeline | 60 feet pipeline | 90 feet pipeline | 120 feet pipeline | 150 feet pipeline |

|---|---|---|---|---|---|

| 320 gallons/hour | 0.87 psi loss | 1.74 psi loss | 2.61 psi loss | 3.48 psi loss | 4.35 psi loss |

| 370 gallons/hour | 1.01 psi loss | 2.03 psi loss | 3.04 psi loss | 4.06 psi loss | 5.07 psi loss |

| 470 gallons/hour | 1.74 psi loss | 3.48 psi loss | 5.22 psi loss | 6.96 psi loss | 8.7 psi loss |

| 630 gallons/hour | 2.75 psi loss | 5.51 psi loss | 8.26 psi loss | 11.02 psi loss | 13.77 psi loss |

| 740 gallons/hour | 3.62 psi loss | 7.25 psi loss | 10.87 psi loss | 14.50 psi loss | 18.12 psi loss |

| 950 gallons/hour | 5.80 psi loss | 11.60 psi loss | 17.40 psi loss | 23.20 psi loss | 29.00 psi loss |

The amounts of water listed in the table correspond to bucket test values of 30, 25, 20, 15, 13 and 10 seconds. 15 seconds is a good value in practice, anything closer to 10 seconds is a very good value. 30 seconds are very close to the limit for meaningful use.

The table shows that the pipeline hardly slows down with smaller amounts of water, but the pressure loss increases sharply with larger amounts of water. If you have such a potent water extraction point, it could be worthwhile to lay a 1 inch pipeline instead of the 3/4 inch standard pipeline. The pressure loss of a 1 inch pipeline is only about a third of that of a 3/4 inch pipeline.

Curves

The calculated losses are based on straight pipes. In a real scenario, however, you also have to incorporate one or the other curve. If these curves are executed as gently as possible, i.e. with a large radius, as recommended, then they are of little importance in the calculation. With smaller amounts of water, the loss is hardly measurable, with the largest amount of water of 950 gallons / hour it is only 0.29 psi, with 740 gallons only 0.14 psi. So you can either neglect that completely or – if you calculate with large amounts of water – simply add 0.70 or 1.45 psi to it.

T-pieces

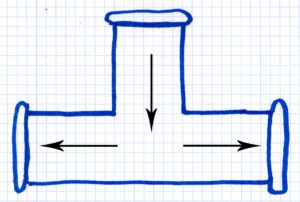

Somewhat greater ist the effect of using L- or T-pieces, ie “L” or “T” -shaped connectors, with which a pipeline section can be guided sharply at a 90 degree angle around the curve or can be split in two pipeline sections.

Example of a T-piece connector with which a water line is divided into two water lines at a 90 degree angle

Due to the sharp 90 degree corners, there is more pressure loss here than when the water is guided gently through a long curve. Again in relation to the standard 3/4 inch pipeline, the pressure loss is not dramatically high in absolute terms, but about twice as large as in the curve described above:

| Amount of water | Pressure loss |

|---|---|

| 320 gallons | 0.07 psi |

| 370 gallons | 0.14 psi |

| 470 gallons | 0.14 psi |

| 630 gallons | 0.29 psi |

| 740 gallons | 0.43 psi |

| 950 gallons | 0.58 psi |

For example, if you have 740 gallons of water and three T-pieces in a sector, you simply add 1.29 psi pressure loss.

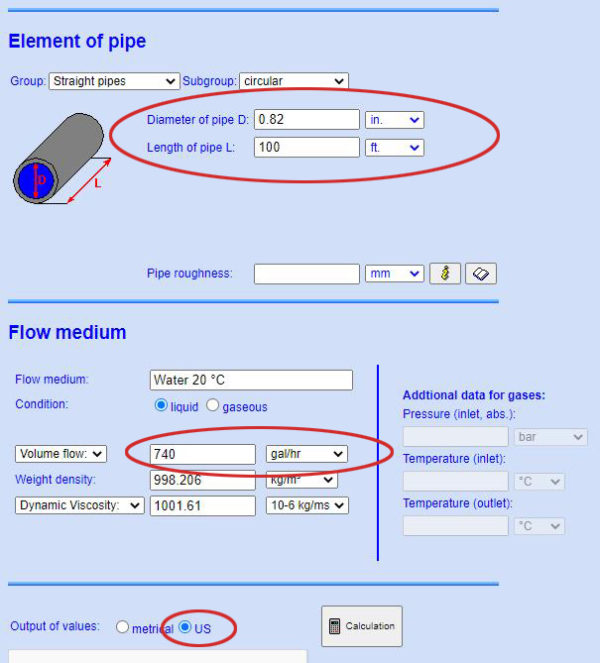

Exact calculation with pressure-drop.com

If you want to know exactly, the website www.pressure-drop.com offers an online calculator with which you can exactly calculate the water pressure loss in pipes. The calculator is preset as standard for the most common “straight pipes” application. In order to calculate the pressure loss, the user has to make three entries:

- The pipe diameter (again the inner pipe diameter is meant)

- The length of the pipe

- The volume flow (= the amount of water that flows through the pipeline)

Below is an example for a standard 3/4 inch pipe, with a pipe length of 100 feet and a volume flow of 740 gallons / hour:

Pressure loss calculator – the entries to be made are marked in red

After confirming by clicking on the “Calculation” button, the pressure loss is shown:

Pressure loss result

You can also calculate the pressure loss for curves and L-pieces (menu item “Bends”) and T-pieces (“Brandings of current”) and for more complex things such as narrowing from a larger to a smaller pipe (“Changes of section”). The application is very quick and easy, a really recommendable and useful online tool!

Link tip: Pressure drop online calculator